WELCOME TO ROTEC TOOLS, LTD

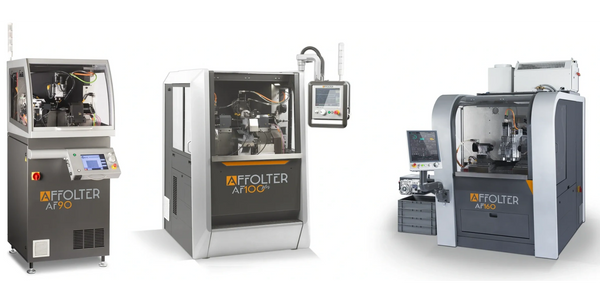

Affolter - CNC Gear Hobbing Machines

Affolter - CNC Gear Hobbing Machines

Affolter - CNC Gear Hobbing Machines

- The Gear Line gear hobbing machines represents a new concept in compact machines

- Powerful, rigid and precise gear hobbing

- Up to 16,000 RPM

- Excellent surface finish

- Long tool life

Lehmann - Rotary Tables

Affolter - CNC Gear Hobbing Machines

Affolter - CNC Gear Hobbing Machines

- Compact, powerful, modular design

- Advanced technology with many high-tech features.

- Direct Drive

Hofmann - Rotary Tables

MAPROX - Solutions for Measuring and Precision Mechanics

Diametal - Grinding Wheels + Gear Hobs

- European style rotary (compact, high-precision, modular design)

- Direct drive

- EDM applications

- Manual dividing rotary tables

Diametal - Grinding Wheels + Gear Hobs

MAPROX - Solutions for Measuring and Precision Mechanics

Diametal - Grinding Wheels + Gear Hobs

- Precision solid carbide gear cutting tools

- Bonded precision grinding tools in Diamond and CBN

- Electroplated precision grinding tools in Diamond and CBN

- Diamond and CBN grinding wheels for top & bottom grinding

MAPROX - Solutions for Measuring and Precision Mechanics

MAPROX - Solutions for Measuring and Precision Mechanics

MAPROX - Solutions for Measuring and Precision Mechanics

- Jaw chucks JF ultra-flat

- Jaw chucks ZF ultra-short

- Collet holders

- Dividers

- Test clamping equipment

Fleury - 5-Axis Linear Transfer Machines

Fleury - 5-Axis Linear Transfer Machines

MAPROX - Solutions for Measuring and Precision Mechanics

- Compact, modular design, 24/7 operation

- From blank to finished part, including basic assembly

- 3-axis or 5-axis vertical milling

FISSO - 3-D Indicator Arms

Fleury - 5-Axis Linear Transfer Machines

FISSO - 3-D Indicator Arms

- Zero-play fine adjustment

- High accuracy

- Various combinations with bases

- Clever central tightening system

- Highest stability

Simatec - Automatic Lubricators

Schunk / Gressel Precision Vises

Simatec - Automatic Lubricators

- Single-point lubrication systems

- Simatherm bearing heaters

- Simatool mounting and dismounting of roller bearings

Greber - Dead and Live Centers

Schunk / Gressel Precision Vises

Simatec - Automatic Lubricators

- Complete range of "High Precision" dead and live centers

- Range of carbide or hardened tool-steel tip

- Live centers with "Load" indicator

- Custom centers

Schunk / Gressel Precision Vises

Schunk / Gressel Precision Vises

Niederhauser - Chucks + Special Fixtures

- Precision vises with mechanical intensifier

- Precision vises with hydraulic or pneumatic intensifier

- Double and centric vises

- Tombstone applications

Niederhauser - Chucks + Special Fixtures

Niederhauser - Chucks + Special Fixtures

Niederhauser - Chucks + Special Fixtures

- Comprehensive range of clamping devices for various metal-cutting industries

- Customized clamping solutions for any application available

AdTime - Burnishing Machines

Niederhauser - Chucks + Special Fixtures

AdTime - Burnishing Machines

- Parts mounted on planished support for drastically improved grinding wheel alignment

- Up to 24 seats: 12 seats per side can be rolled simultaneously

NEW HEMO Precision Vises

Niederhauser - Chucks + Special Fixtures

AdTime - Burnishing Machines

- Precision vise

- Compact, powerful design

- Many varieties

Please contact us for more information!

Visit our Online Store

Contact Us

EVENTS

Come see us in person!

IMTS Booth 237223